In custom printing, durability means much more than surviving a wash cycle or two. True durability refers to how well a print holds up over time, maintaining its vibrancy and integrity under various conditions. It’s about resisting wear and tear, surviving repeated washes, and looking as good as the day it was made.

At OMO Transfer, we specialize in Direct-to-Film (DTF), Glitter DTF, and UV DTF printing services, offering prints that stand the test of time. Here’s an in-depth look at print durability and how to maximize it.

What Does Print Durability Mean?

Print durability is the print’s ability to withstand repeated use and exposure while retaining its color, flexibility, and resistance to cracking or peeling. A truly durable print will maintain its appearance and quality for the lifespan of the garment itself.

Are DTF Transfers Durable?

Yes, DTF transfers are among the most durable printing options available. DTF stands out for its ability to handle extensive washing and drying cycles without losing color or detail, rivaling traditional screen printing in terms of durability.

OMO Transfer’s DTF prints are designed to exceed expectations, outperforming other heat transfer methods with their resistance to cracking, fading, and peeling. This makes DTF ideal for high-use items, from sports jerseys and work uniforms to everyday apparel and promotional items.

Factors Affecting Print Durability

Several factors play a role in how long a print will last, especially with DTF transfers:

-

Quality of the Transfer: High-quality DTF transfers form the foundation of a durable print. At OMO Transfer, our transfers are crafted for vibrant color retention, strong adherence, and long-lasting performance.

-

Design Structure: Simple, bold designs with solid shapes tend to be more durable than intricate designs with small parts or thin lines, which are more prone to wear.

-

Fabric Type: Different fabrics interact with DTF transfers in unique ways. Cotton and cotton blends typically offer the best results for longevity, but DTF also works well on a range of other materials.

-

Application Process: Applying the transfer correctly with the right balance of heat, pressure, and timing is essential. Follow OMO Transfer’s heat press instructions for DTF to ensure an optimal bond with the fabric.

-

Environmental Exposure: Frequent exposure to sunlight, extreme weather, or heavy physical activity can affect the print’s longevity.

-

Garment Care: Proper garment care—such as washing inside out, using mild detergents, and avoiding high heat in the dryer—significantly extends the lifespan of a DTF print.

How Long Do DTF Transfers Last?

When given the proper care and under typical conditions, a DTF transfer can last 50 to 100 washes or more. OMO Transfer’s DTF prints are built to endure, often outlasting the garment itself. High-use garments like athletic jerseys or outdoor workwear may show signs of wear sooner, but the durability of a quality DTF print is impressive, ensuring vibrant designs for years.

Tips for Maximizing Print Durability

To help your custom DTF prints last as long as possible, consider these tips:

- Start with High-Quality Transfers: At OMO Transfer, we ensure that our DTF transfers are bright, detailed, and resilient.

- Select the Right Fabric: Cotton or high-cotton blends tend to yield the best results, although DTF is versatile across many fabrics.

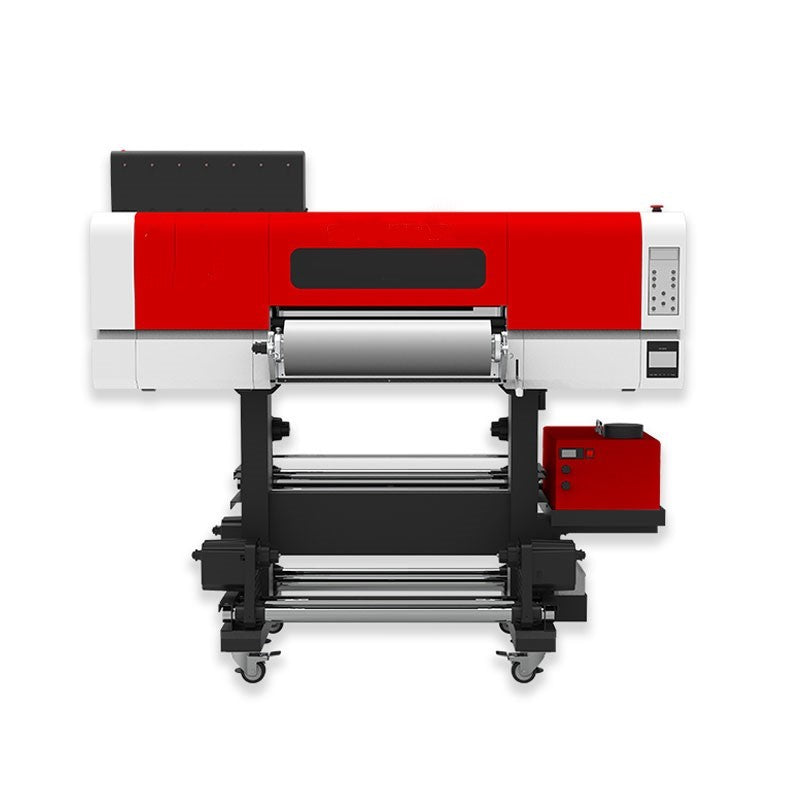

- Invest in a Quality Heat Press: A professional-grade heat press ensures better, longer-lasting results than an iron or handheld heat press.

- Follow the Application Process: Adhere closely to recommended pressing guidelines to ensure a strong bond with the fabric.

- Practice Proper Garment Care: Wash garments inside out, use mild detergents, and line dry when possible. If using a dryer, choose a low-heat setting.

- Avoid Harsh Environmental Conditions: Limit exposure to direct sunlight, extreme weather, and rough physical activities when possible to maximize longevity.

Comparing Durability Across Print Methods

Different printing methods offer various levels of durability. Here’s a quick comparison:

- DTF Transfers: Highly durable and versatile, ideal for lasting prints across various fabrics.

- Sublimation: Extremely durable, as the ink becomes part of the fabric. However, it’s limited to polyester and polyester blends.

- Screen Printing: Known for durability, but print quality may degrade over time with wear and washing.

- Vinyl (Cut or Printed): Durable for simple designs but can peel or crack over time, especially with frequent washing.

- Heat Transfer Prints (Paper): Accessible but less durable, often showing signs of wear, fading, or cracking after many washes.

- Direct-to-Garment (DTG): Great for detail but may fade with frequent washing.

To learn more, check out OMO Transfer’s guide on printing methods for a detailed comparison and which option may be best for your needs.

Embrace the Durability of DTF with OMO Transfer

At OMO Transfer, durability is our priority, and our DTF transfers are made to last. Whether you’re producing high-demand workwear, athletic gear, or casual apparel, our DTF, Glitter DTF, and UV DTF options provide the durability, color vibrancy, and flexibility your designs need to make a lasting impression.

With OMO Transfer as your trusted partner, you can be confident in the quality and longevity of your custom prints. Let us help you bring your designs to life with vibrant, resilient DTF transfers that truly stand the test of time.