In the dynamic realm of printing technologies, two methods have been gaining traction for their adaptability, vividness, and user-friendliness: DTF (Direct to Film) and UV DTF. Whether you're an experienced practitioner or new to printing, grasping the advantages of these methods and their application can redefine your projects. Let's delve deeper!

Understanding DTF and UV DTF:

DTF, or Direct to Film, involves transferring designs directly onto a specialized film, which is then heat-pressed onto the intended surface. This approach ensures remarkable color accuracy, meticulous detail retention, and compatibility with diverse materials, making it suitable for various applications, from garments to promotional items.

UV DTF advances traditional DTF by incorporating UV-curable inks. This enhances color vibrancy, durability, and adaptability in printing on different substrates, including plastics and metals.

The Advantages of DTF and UV DTF:

Vivid Colors: Both DTF and UV DTF yield captivating, true-to-life colors that enhance design impact.

Precise Detail Preservation: Whether it's intricate patterns or small text, these methods excel at maintaining fine details with utmost clarity.

Versatility: DTF and UV DTF enable printing on fabric, plastic, wood, or metal, offering unmatched versatility for creative expression.

Durability: With resilient prints resistant to fading, cracking, and peeling, DTF and UV DTF creations endure even under challenging conditions.

Cost-Efficiency: Featuring streamlined production processes and minimal wastage, DTF and UV DTF provide cost-effective solutions for projects of all scales.

Applying DTF and UV DTF:

Prepare Your Design: Craft or select your design using graphic design software, ensuring it meets the resolution and format specifications for DTF printing.

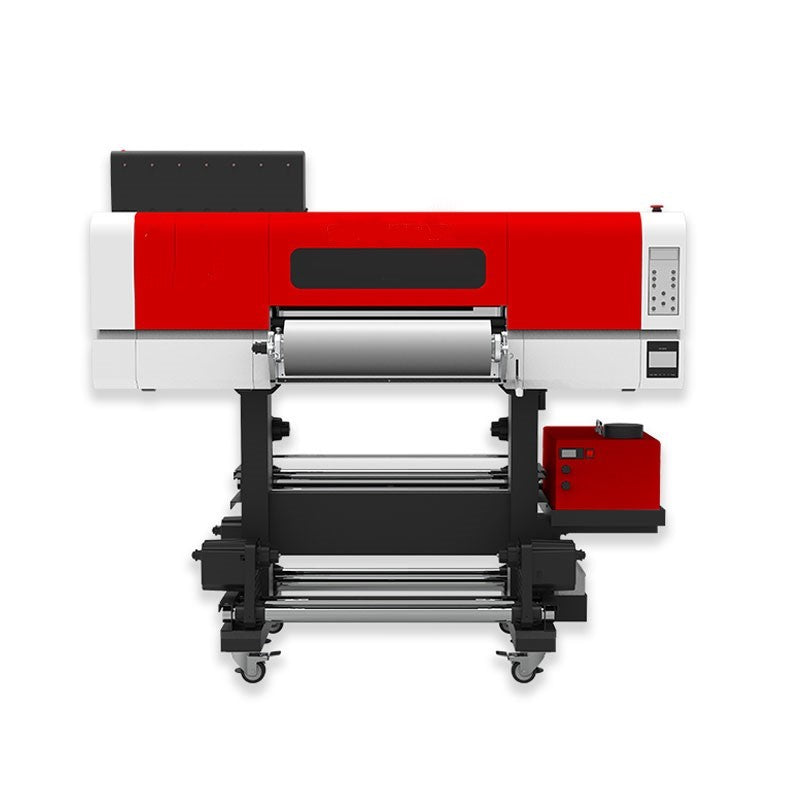

Print Your Design: Utilize a DTF or UV DTF printer to transfer your design onto the specialized film, ensuring precise alignment and color calibration.

Prepare the Surface: Clean and prep the substrate surface, removing any impurities like dust or debris.

Heat Transfer: Employ a heat press machine to transfer the design from the film to the substrate, applying heat and pressure per the manufacturer's guidelines.

Cooling and Finalization: Allow the transferred design to cool thoroughly before peeling off the film, revealing the vibrant print beneath. Consider additional curing processes for UV DTF prints to enhance durability.

Enjoy Your Creation: Once the transfer is complete, admire your masterpiece and explore the endless possibilities of DTF and UV DTF printing!

In essence, DTF and UV DTF open up a world of opportunities for printing enthusiasts, artists, and businesses alike. With their unparalleled color vibrancy, meticulous detail retention, versatility, and durability, these methods are reshaping the printing landscape. So why wait? Immerse yourself in the realm of DTF and UV DTF printing today and unleash your creativity like never before!